Kjøkken-trailer

Har du behov for en mobil kjøkkenløsning med stor kapasitet kan dette være løsningen. Dette kjøkkenet har kapasitet på 3.000 måltider pr døgn. Aktuelt på festivaler, større arrangement, events osv. Kjøkken-traileren kan selvsagt bygges opp etter kundens eget behov og ønsker. Alt leveres CE-godkjent med de nødvendige sertifikater. Se eksempel på tilbehør som traileren kan utstyres med ved å trykke her.

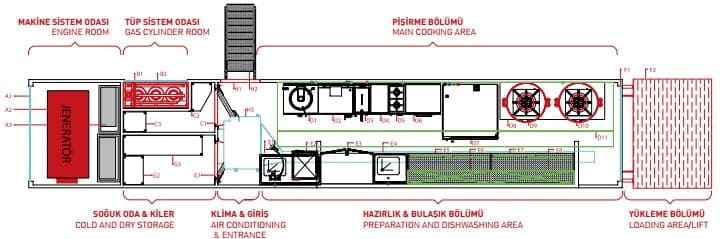

Link til eksempel prosjekt med inndeling av soner og utstyr er forklart her.

Produsenten Mobilchef som er en del av AKE Group lokalisert i Konya i Tyrkia. Selskapet ble etablert i 2018 og produserer i tillegg til kjøkkentrailere også foodtrucks, kjøkkencontainere, mobile pizzaovner, militære kjøkkenløsninger, matvogner osv. Alt leveres CE-godkjent og klart for det europeiske markedet.

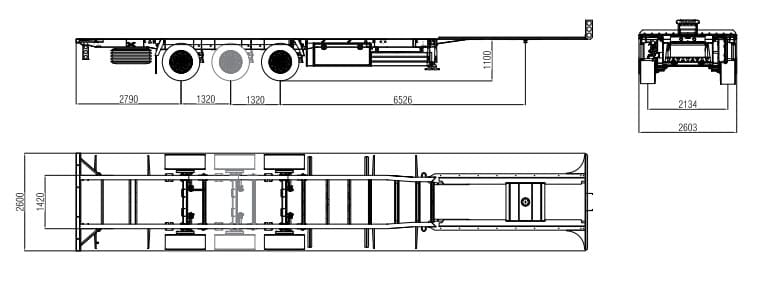

Standard Trailer

General & Technical Specifications

Axle: 3×9000 kg carrying capacity.Axle set consists drumbrake or disc.

Chassis: Chassis produced from by special materials as “I” section through submerged automation welding. 98/91 EEC standards conformity.

Tire and Rim: 6+1 tubeless tire along with steel rim.

Brakes: Automatic load adjustment valve and RSS (Balance &Road Bend System) which has compliance with 71/320 EEC and 2002/78 EC standards.

Tag Axle Lift: Operates in order to avoid tyre wear and provides safety ride on road turns.

Landing Leg: With the 24 ton of carrying capacity ,double speed imported mechanical legs.

Air Suspension: Height adjustment system within the manuel lifting. Suitable Dashpot in order to limit excessive axle movements and parabolic Z turnouts.

Lenght: 13550 mm

Rear Bumper: Rear bumper mounting carrier and 1 no of parking mounting which has compliance with 70/221/AT standard

Dye: The dying process right after cleaning as per following; as first step we apply sandblasting through metal grit(metal) supply , there is covering with phospate , and then 2 layers of Epoxy dying.As final dying stage ; we place demanded acrylic enamel before ovendrying process.

Electrical Equipment and Lighting: 3 pieces amber lighting on sides,parking lamp,warning triangle (E approved electric system) on back side along with 2×7 pinned electric connection

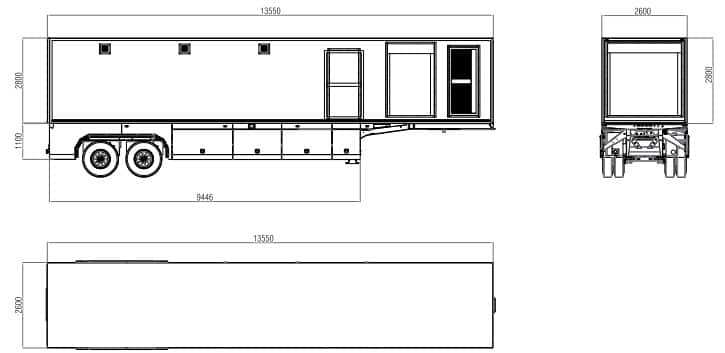

Optional Trailer

General & Technical Specifications

Axle: 3×9000 kg carrying capacity.Axle set consists drumbrake or disc.

Chassis: Chassis produced from by special materials as “I” section through submerged automation welding. 98/91 EEC standards conformity.

Tire and Rim: 6+1 tubeless tire along with steel rim.

Brakes: Automatic load adjustment valve and RSS (Balance &Road Bend System) which has compliance with 71/320 EEC and 2002/78 EC standards.

Tag Axle Lift: Operates in order to avoid tyre wear and provides safety ride on road turns.

Landing Leg: With the 24 ton of carrying capacity ,double speed imported mechanical legs.

Air Suspension: Height adjustment system within the manuel lifting. Suitable Dashpot in order to limit excessive axle movements and parabolic Z turnouts.

Lenght: 13550 mm

Rear Bumper: Rear bumper mounting carrier and 1 no of parking mounting which has compliance with 70/221/AT standard

Dye: The dying process right after cleaning as per following; as first step we apply sandblasting through metal grit(metal) supply , there is covering with phospate , and then 2 layers of Epoxy dying.As final dying stage ; we place demanded acrylic enamel before ovendrying process.

Electrical Equipment and Lighting: 3 pieces amber lighting on sides,parking lamp,warning triangle (E approved electric system) on back side along with 2×7 pinned electric connection

Upper Structure

General & Technical Specifications

Upper structure made by white colored monoblock composed material for interior and outside. XPS vacuuming technic applied between interior and outside jackets.

Floor: 130 mm thickness of polyurathane and surface within plywood plates , main flooring covered within 2 mm thickness of nonslip engvared aluminum plates.

Walls: Interior side covered within stainless steel plate with 60 mm thickness of composed panel.On the area of cooking equipments , there is 30 mm thickness of ceramic insulation ( up to 1200 celcius degree) applied along with steel covering in order to protect polyurathane insulation.

Ceiling: Produced by 80 mm insulated composed material.

Rear Cover: In order to provide easier material handling, 2 meter long aluminium made area is placed on the rear wall of upper structure.

Options

- Wool insulated interior wall covering.

- Doors and Windows in accordance with project.

- Wall partitions in accordance with project.

Optional Features

WATER TANK

It provides Mobile Kitchen’s water need by being under the vehicle.It is isolated with 30 mm isolation between double stainless steel sheet metal against the possibility of freezing in cold weathers.In order to prevent vibration during the transportation,clean and waste water tanks have been departmentalized with jetty.There is an indicator that indicates the amount of water in it.Through the agency of hydrophore system,the water is given to all points that need water.

ROLLING SHUTTER SYSTEM

Isolated, air conditioned,high strength shutters are placed to desired place at vehicle.Shutters can be controlled with mechanic and remote control

FOOD STORAGE UNIT

It is used to safekeep the foods that need to be kept cold.According to need and demand, it is projected to work between -25 °C – +10°C.The volume of room is determined by customer.Neutral pantry can be used to safekeep the dry foods.

WORKING TABLES

It is designed to prepare the foods for the customer needs.It can be produced as portable ,constant cabinet and shelf in order to gain place during the journey.It is produced by complete stainless steel.

WALL CABINETS

It is used to safekeep the foods and transport the overbank equipments.There are lock systems at all cabinets.It is projected according to customer demand and produced by complete stainless steel.

FOLDING PLATFORM

The platforms that dont protrude to the outer surface of moving vehicle are used by being opened to the sides during food distribution.Safet food distribution is done by attaching stairs and railing to the dehiscent platform systems. Platforms can carry minimum 500 kg/m² and every stair step has 200 kg standing capacity.Also stair steps prevents the possibility of slipping and falling.

ANTI – BACTERIAL FLOOR COVERING

Ground sheathing is applied as pool type by material that is durable against abrasion and impact. It must be anti-bacterial featured and suitable to food hygiene standards. Sheathing is durable against the stretch and expansion that happens in system. Sheathing is applied completely to prevent formation of microbe and bacteria.Dull surfaces has features of nonslip,hygiene,high mechanic and chemical strength

THE MACHINE ROOM

There is generator system that can provide all electric need according to project that is applied to the vehicle.The generator is installed to the ground as it can stop the vibrations that may occur in system.The vehicle is projected to be fed all electrıc need from the generator or external energy source..

HYDRAULIC TAIL LIFT

In order to simplify the work there is height adjustment system with lowering and lifting, parabolic Z scissors and hydraulic damper as movement restrictive fort the axle.The hydraulic elevator system that can be adjusted with control panel,can be used parallel to the rear lids. It has 1000 kg. carrying capacity.

DISHWASHER UNIT

This unit is used both to wash the foods during the food preparation and to wash the dishes after process.This unit can be projected to include dishwasher according to customer demand.

GAS SYSTEM WITH LPG TANK

Instead of LPG cylinder we can produce with fixed LPG tank. So that you can fill the tank from gas station. It is easier to use then LPG cylinder. You don‘t need to move LPG cylinder.

ALUMINUM FLOOR COVERING

Floor covering made by aluminum which has compliance with food hygiene standards. It has durability agains wear and hits with nonslip,hygienic and heavy duty structure.

PREPARATION EQUIPMENTS

The fastest assistants of chefs are meat mincer,vegetable cutter,potato peeler.. etc. machines during food preparation.These CE certificated machines that are produced by our company are immobilized to the operating benches to prevent falling during the operation.According to customer demands,different products can be used.

COOKING EQUIPMENTS

Our Company uses CE certificated our own products that are produced by complete stainless steel.Convection Ovens,Furnaces,Boiling Bowls and Pans are applied to Mobile Kitchen according to customer demands.

AIR CONDITIONING SYSTEM

The filtered chimney hood and aspirator system is used to remove the smell and vapor that occurs during cooking to outside.Air conditioning system is used in the kitchen to provide comfortable operating contidions .Air conditioning system may be slotted or split type.The air is delivered through the agency of isolated double paries stainless steel duct at slotted air conditioning system.

Bli den første til å omtale “Kjøkken-trailer” Avbryt svar

Relaterte produkter

Varen har utgått fra vårt sortiment.

Omtaler

Det er ingen omtaler ennå.